GURUPRASAD N

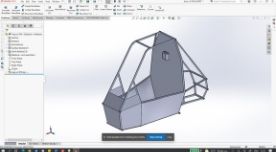

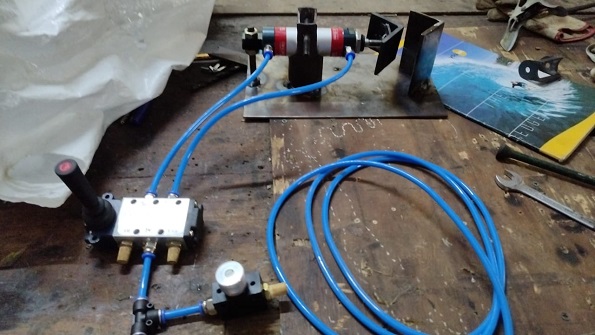

BE-Mechanical (2022-26) | Vice-Captain | Rollcage @ CEG Motorsports

Final year mechanical engineering student with a strong passion for automobile design and engineering. Throughout my studies, I always look for new challenges and opportunities to learn. I have good problem-solving abilities and eagerness to learn, and I'm excited about contributing my skills and enthusiasm to the field of automotive engineering.