JAI SURIYA R P

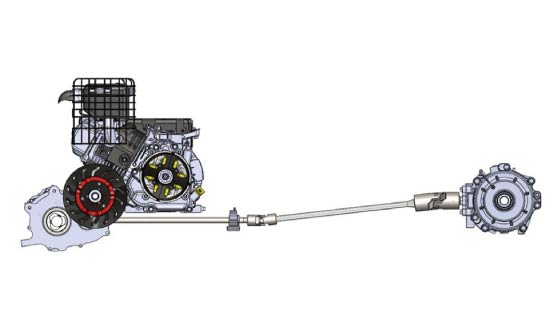

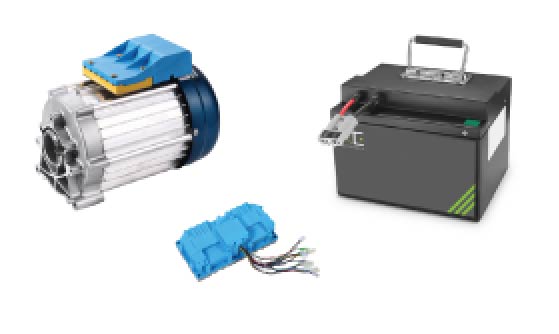

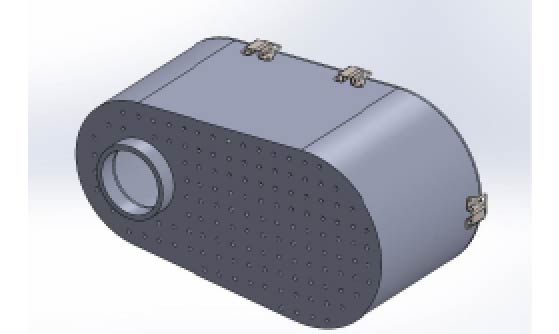

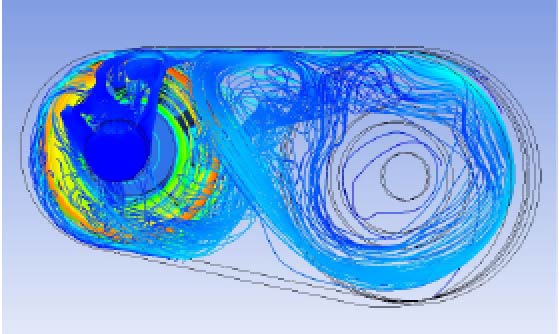

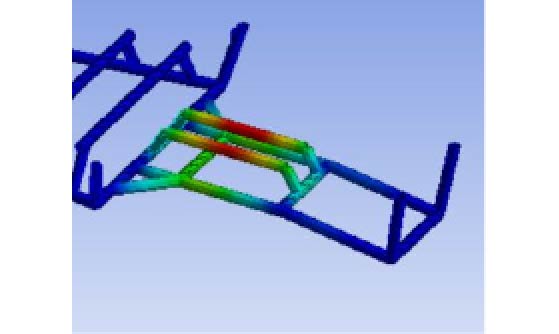

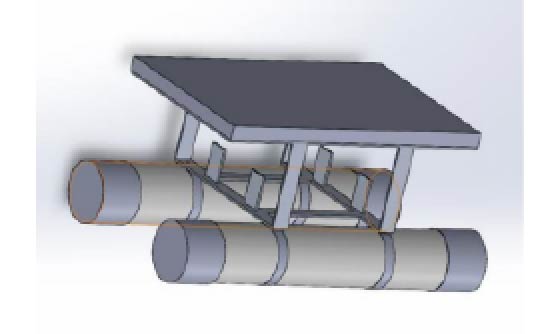

BE-Mechanical (2020-24) | Captain @ CEG Motorsports

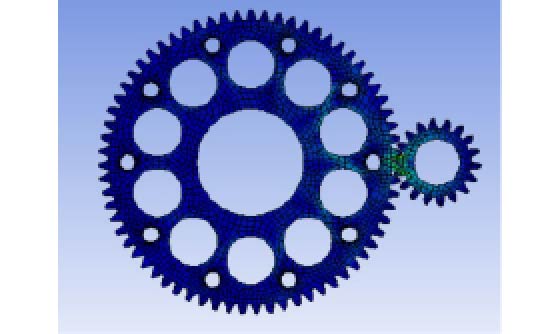

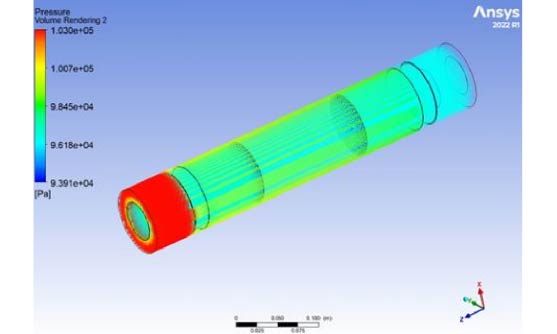

A competent mechanical engineer who likes management as well. A skilled designer, CAE analyst and a creative problem solver, who has experience in using these skills in a team environment, with a goal of winning trophies.