KAVIARASAN JS

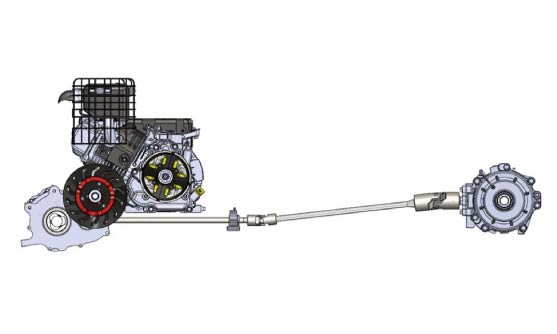

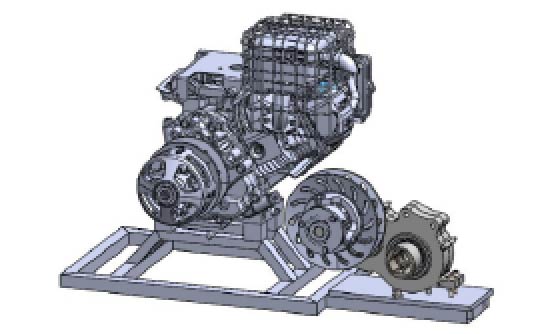

BE-Mechanical (2020-24) | Alumni Relations Lead | Drivetrain @ CEG Motorsports

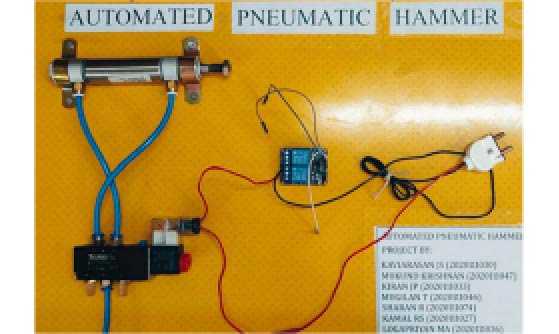

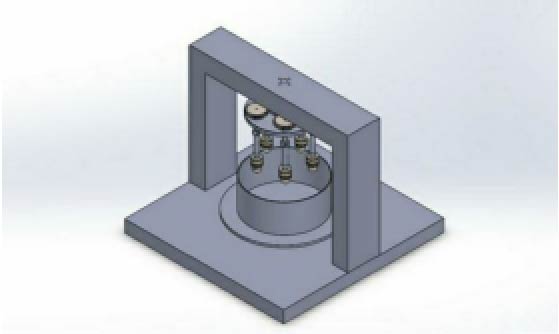

I'm Kaviarasan JS, an aspiring Mechanical Engineering student with a passion for automobiles, mechatronics and robotics. I have hands-on experience in automotive projects through my involvement with the SAE Collegiate Club. I thrive on problem-solving and have a keen interest in design, research, and innovation.