KEERTHI SRI S

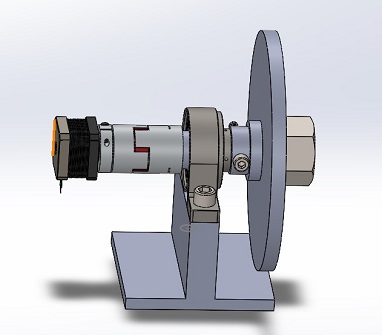

BE-Mechanical (2022-26) | Vehicle Integration and Statics Lead | Suspension @ CEG Motorsports

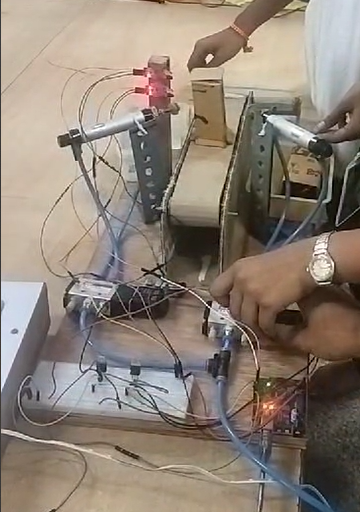

I am Keerthi Sri, Enthusiastic Mechanical Engineering student who still gets excited about figuring out how things move and work. With a mix of classroom theories, hands-on experience, and plenty of trial-and-error, I’m learning to turn curiosity into practical solutions