NITHYASRI

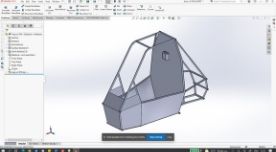

BE-Mechanical (2021-25) | Senior Rollcage Vertical Member @ CEG Motorsports

A Dynamic Mechanical Engineering Student who always has an endless thirst for knowledge. A dedicated and organized person trying to achieve excellence with my conscious efforts. Equally effective in a leadership or hands-on role. Special interest in expanding my knowledge in the field of Design and Automobile. Willing to find a relevant opportunity to mould myself.